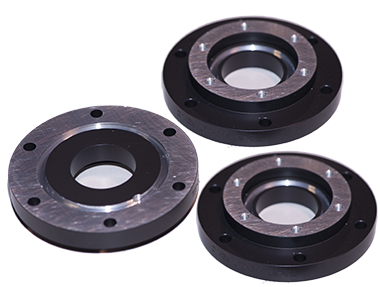

Anodized Aluminum

Type II Anodizing

Anodizing is a process for producing decorative and protective films on parts made from aluminum and its alloys. Anodizing is an electrochemical conversion process that forms an oxide film, usually on aluminum, in an electrolyte (chemical solution). Oxide from the anodizing process produces a coating which provides greater abrasion protection and resistance to corrosion. The oxidefilm changes the surface of the aluminum which provides greater abrasion resistance as well as increased corrosion protection. The finish will not only build up the aluminum oxide on the surface, but will also penetrate into the material the same amount. This oxide increases durability and provides electrical insulation .

Type II anodizing is available in two forms Class 1 clear (non dyed) or Class 2 (dyed)

Type II Anodizing Coating Thickness

Coating Thickness of Type II anodizing will vary from .0002 inches for clear anodizing to.0008 inches for certain color anodizing. Thicker coatings will provide harder more durable protection for the aluminum parts.

Common things that use Type II anodizing:

- Marine products

- Motorcycles

- Architectural aluminum parts (Door frames, window frames)

- Automotive

- Electrical products